Organic Dairy Housing Standards

Back

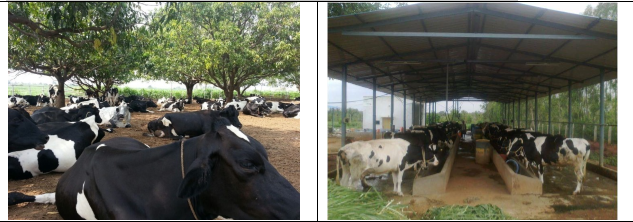

Standards for Animal Housing management in Organic Dairy Farming

1. Adequate natural bedding materials are necessarily required under ODF.

• Sawdust and wood shavings: When properly screened and dried, sawdust can provide an effective bedding option for dairy cows. A drawback to using sawdust is that it can facilitate pathogen growth when damp, although adding lime to the bedding can reduce the risk. Wood shavings can serve as surface bedding, but they can be more expensive and less absorbent than sawdust.

• Straw: Chopped straw can provide a comfortable environment for cow bedding. However, it’s essential to change the bedding frequently, as heavily soiled straw can promote the growth of pathogens. Using straw with a small particle size will increase animal comfort and reduce the breakdown time.

• Compost: Compost provides an organic bedding option for dairy cows that works well in open barn environments. The use of composting does require twice-daily aeration during milking, as well as the addition of sawdust or wood shavings as needed.

• Proper ventilation is also essential due to the manure content. When the compost pack reaches four feet in height, farmers can then remove it from the barn and use it to fertilize their fields.

In recent years, efforts have been undertaken to improve welfare and overall-health of dairy cows by providing a higher level of comfort regarding the housing environment.

Housing system and resting surface have influence on milk yield and reproductive performance as much as feeding and keeping methods in dairy herd.

Proper bedding and flooring provide soft area for animals to lay for rest and help to improve their productive and reproductive performance.

2. Bedding materials that are normally consumed by the animals should be organic

3. Sufficient free movement and accessibility to fresh air and natural daylight is essential besides protecting them from excessive sunlight and rain.

4. Animals should have access to clean fresh water all times to meet their water requirements under ODF.

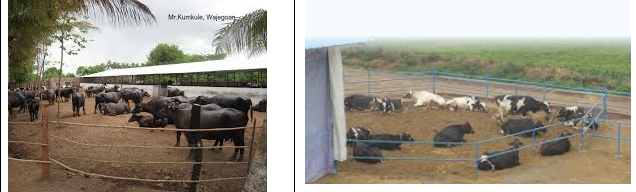

5. Herd animals should not be kept individually under ODF.

6. Tethering is generally not allowed in ODF.

7. Even in ODF animals can be confined for specific reasons, such as, milking, for some medical procedures, controlled grazing, during night time and for health, safety and well being of animal.

8. In ODF, as far as possible locally available materials may be used for construction of dairy animal dwellings.

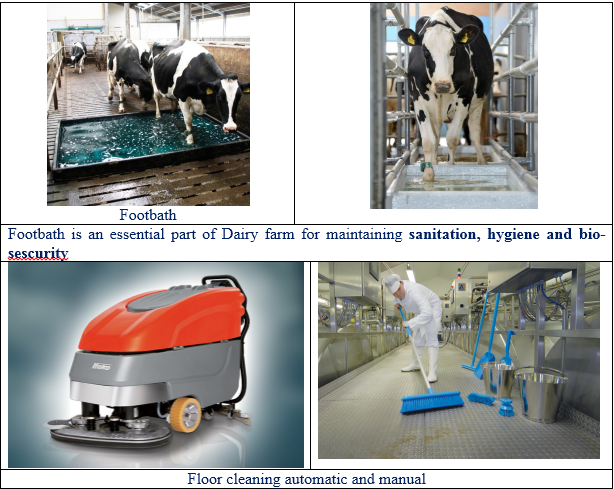

9. Maintenance of sanitation, hygiene and bio-sescurity are essential in ODF.

Bio-security: means the protection of farm animals against diseases and includes measures designed to protect the animal population against harmful biological or biochemical substances.

Bio-security refers to various measures that are undertaken to stop the spread or introduction of harmful organisms to animals, human and plant life.

The following bio-security measures are followed in animal farms to control the diseases.

(i) Restricted access to livestock farm: A livestock farm is secured by fences or walls to avoid the unauthorized entry of any person. By providing fences and walls, entry of wild animals can also be checked.

(ii) Provision of footbath: A footbath of disinfectant like solution of phenol or slaked lime or solution of copper sulphate is kept at the entry and exit points of a farm gate to prevent the spread of pathogens in animals.

(iii) Use of personal protective equipment (PPEs): Animal health workers wear apron, gloves, mask, head mask and gumboots for their safety and security while handling the animals. They need to wash their hands with soap and sanitizers frequently.

Dairy Hygiene

A. Requirements for premises and equipment

Milking equipments and premises where milk is stored, handled or cooled must be located and constructed so as to limit the risk of contamination of milk.

Premises for the storage of milk must be protected against vermin, have adequate separation from premises where animals are housed and, where necessary to meet the requirements laid down in Part B, have suitable refrigeration equipment.

Surfaces of equipment that are intended to come into contact with milk (utensils, containers, tanks, etc. intended for milking, collection or transport) must be easy to clean and, where necessary, disinfect and be maintained in a sound condition. This requires the use of smooth, washable and non-toxic materials.

After use, such surfaces must be cleaned and, where necessary, disinfected. After each journey, or after each series of journeys when the period of time between unloading and the following loading is very short, but in all cases at least once a day, containers and tanks used for the transport of raw milk must be cleaned and disinfected in an appropriate manner before re-use.

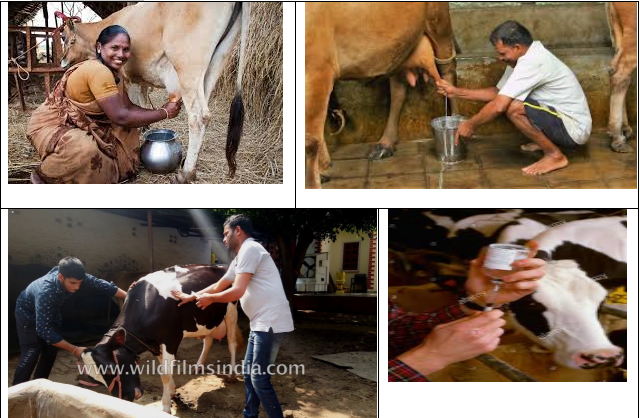

B. Hygiene during milking, collection and transport

Milking must be carried out hygienically, ensuring in particular: (a) that, before milking starts, the teats, udder and adjacent parts are clean; (b) that milk from each animal is checked for organoleptic or physico-chemical abnormalities by the milker or a method achieving similar results and that milk presenting such abnormalities is not used for human consumption; (c) that milk from animals showing clinical signs of udder disease is not used for human consumption otherwise than in accordance with the instructions of a veterinarian; (d) the identification of animals undergoing medical treatment likely to transfer residues to the milk, and that milk obtained from such animals before the end of the prescribed withdrawal period is not used for human consumption; and (e) that teat dips or sprays are used only if the competent authority has approved them and in a manner that does not produce unacceptable residue levels in the milk.

Immediately after milking, milk must be held in a clean place designed and equipped to avoid contamination.

It must be cooled immediately to not more than 8°C in the case of daily collection, or not more than 6°C if collection is not daily.

During transport the cold chain must be maintained and, on arrival at the establishment of destination, the temperature of the milk must not be more than 10°C.

Food business operators need not comply with the temperature requirements laid down in points 2 and 3 if the milk meets the criteria provided for in Part III and either: (a) the milk is processed within two hours of milking; or (b) a higher temperature is necessary for technological reasons related to the manufacture of certain dairy products and the competent authority so authorises.

C. Staff hygiene

Persons performing milking and/or handling raw milk must wear suitable clean clothes.

Persons performing milking must maintain a high degree of personal cleanliness. Suitable facilities must be available near the place of milking to enable persons performing milking and handling raw milk to wash their hands and arms.

Surfaces of milking and cooling equipment which come into contact with milk are the main source of milk contamination, and are frequently the principal cause of consistently high bacterial counts.

10. Animals of two different species shall not be kept together as per ODF standards

11. Indigenous dairy cow require 3.5 and 7 square meters per head floor space as covered and open area respectively.

12. Buffaloes/ cross bred cows require 4 and 8 square meters per head floor space as covered and open area respectively.

13. Under ODF a maximum of 50 cows/ buffaloes can be reared in one shed.

14. Under ODF a maximum of 12 young calves can be reared in one shed.

15. Under ODF a maximum of 30 old calves can be reared in one shed.

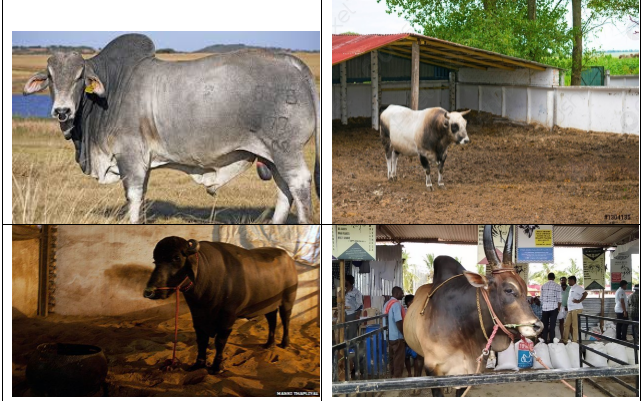

16. A breeding bull requires 12 and 20 square meters per head floor space as covered and open area respectively under ODF.