Organic Dairy Standard Animal Welfare

Back

1. Animals need to be protected from predation by wild and feral animals.

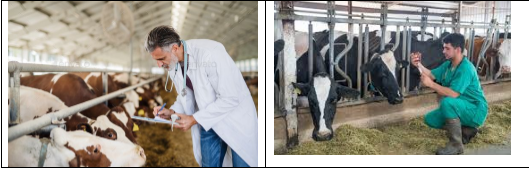

2. Dairy animals must be regularly visited, monitored and inspected in ODF.

3. When welfare and health problems occur in dairy farms, appropriate management adjustments are needed to be implemented (e.g. reducing stocking density).

Animals must be treated in a humane manner that causes least possible stress and suffering.

5. In ODF no sick animals should be put to work.

6. In ODF child labour is not allowed.

7. In ODF, dairy animals shall not be treated with synthetic tranquilizers or stimulants prior to or during transport.

Transport of Cattle and buffalo

General conditions for transport of animals

• Healthy animals should be transported and a qualified veterinarian should certify it.

• Young animals should be separated from adult animals and advanced pregnant state animals should be separated from other animals.

• When animals are transported from endemic area, necessary permission should be obtained from concerned authorities for proper health condition.

• 14 days prior to transportation necessary vaccination procedure should be completed for the particular livestock.

• During transport all the livestock should be given humane treatment

• Sufficient quantity of feed and fodder should be carried during transport

• The vehicle should be examined for cleanliness, the floor and walls shall be undamaged and should be free from nails and other sharp edges

• The vehicle should be sprayed with disinfectant solution

• Materials for bedding such as straw or hay should be placed on the floor to avoid injury and the bedding should not be less than 5 cm thickness

• Animals during transport should not be tied up at leg.

• Each consignment shall bear a bold red label showing the following particulars

o Number and kind of animals loaded

o Name and address and telephone number of the consignor (sender) and consignee (receiver)

o Quantity of ration to be fed

o Consignee should be informed about the train or vehicle in which the consignment of cattle is sent and its arrival time in advance

• In case of journey for more than 12 hours an attendant should be present at all the time and should ensure the proper conditions are maintained during transport.

• Cattle, sheep and goat should be unloaded by every 8 hours and should be watered. The attendant should not permit the sheep and goat to sit down during transit.

• Apart from the above general condition some species of livestock require specific conditions for transport and it also depends upon the mode of transport.

General conditions for train transport

• Animals shall be transported by passenger trains only. In areas where such trains are not run, the equines may be transported by goods trains provided that special precautions are taken.

• Ordinary Cattle wagon when used for transportation of horses, ponies, mules and donkeys along with their foals, shall carry not more than 6 of these animals on broad gauge, 4 on meter gauge and 3 on narrow gauge. Attendants shall be allowed to travel along with the animals in each wagon.

• In extreme summer, water shall be sprinkled over the wagons by the railway authorities to bring down temperature; ice cubes in specially made containers may be placed inside the wagon if recommended by veterinarian.

• Every wagon shall have 2 attendants if the animals are more than 2 in number.

• Animal shall be loaded parallel to the rails facing each other.

• Material for padding (Kapok) such as paddy straw shall be placed on the floor to avoid injury if an animal lies down. This shall not be less than 6 cm thick.

• Rations for the journey shall be carried in the middle of the wagon.

• To provide adequate ventilation the upper door of one side of the wagon shall be kept open and properly fixed.

• This door of the wagon shall have wire gauge welded to it to prevent burning cylinders from the engine entering the wagon and leading to the outbreak of fire.

• 2 breast bars shall be provided on each side of the wagon one at a height of 60 to 90 cm and other at 100 to 110 cm.

• Valuable animal shall be transported in EH or EHH horse box. These shall be provided by the railways.

General conditions for Sea transport

• All ships detailed for conveying animals shall be inspected for fittings by a board consisting of a marine and a veterinary officer.

• The ship may preferably be of shelter deck type and have ample mechanical ventilation, good drainage and arrangements for exercising the animals.

• Horses may normally be accommodated in a single stalls and mules in pens. Each pen holding 4 to 5 mules.

• Providing portholes and permanent air trunks or electric powers on all decks shall ensure more ventilation. Exhaust fans shall be installed to below out foul air.

• The pens shall be mucked out twice day decks scrubbed once every 24 hours. This shall be done when animals are being exercised.

• All standings shall be towards the ship with heads facing inwards.

• Length between breast rail and back lining shall be 2 metres. Breast rails shall be 1.1 m from the platform.

• Passage between 2 rows of pens should be not less than 1.5 metres.

• Parting boards between pens shall be 3 metres.

• To avoid distress especially during hot weather the ship may sail immediately after embarking.

• Entries (stallions) shall not be kept in same decks.

• Clots and fillies shall be kept on the exposed decks.

• A pharmacy and spare stalls for 5% animals shall be made available.

General conditions for Air transport

• In aircrafts animals are either secured in crates of 2 to 3 horses each or kept tied in pens 4 to 5 to each pen.

• The floors of aircrafts are provided protected by a thick layer of wood shavings and covered with polyethylene sheets. Sides of the body are well padded.

• All animals shall be administrated tranquilizers before loading. If an animal becomes considerable within the aircraft it shall be destroyed.

• All aircraft for transporting animals shall be inspected for fitting etc by a board comprising an air force and veterinary officer.

• Loading shall be effected through ramps or lifts.

• An attendant shall accompany the animal consignment.

• A veterinary first-aid kit with the veterinarian shall always be available in the aircraft.

• Coir matting shall be placed on the floor so that loaded animal does not produce any sound during journey.

• Hay bundles shall be placed in between the hind legs and sides of the aircraft.

Transport of Cattle

• It must be accompanied with a valid health certificate indicating fitness of the animals for transport and their selves being free from any contagious or infections disease and in the absence of this certificate, the carrier shall not accept the consignment; the average space provided per cattle in railway wagon vehicle shall not be less than two square meters; hungry and thirsty cattle should not transported; cattle in advanced pregnancy shall not be mixed with young cattle to avoid stampede during transportation .

Transport of cattle by train

• The average space provided per cattle in Railway wagon or vehicle shall not be less than two square metres.

• Suitable rope and platforms should be used for loading cattle from vehicles.

• In case of railway wagon the dropped door of the wagon may be used as a ramp when loading or unloading is done to the platform.

• Cattle shall be loaded after they are properly fed and given water.

• Cattle in advanced stage of pregnancy shall not be mixed with young cattle in order to avoid stampede during transportation.

• Watering arrangements on route shall be made and sufficient quantities of water shall be carried for emergency.

• Sufficient feed and fodder with adequate reserve shall be carried to last during the journey. Adequate ventilation shall be ensured.

• When cattle is to be transported by rail. An ordinary goods wagon shall carry not more than ten adult cattle or fifteen calves on broad gauge, not more than six adult cattle or ten calves on metre gauge, or not more than four adult cattle or six calves on narrow gauge.

• Every wagon carrying cattle shall have at least one attendant. Cattle shall be loaded parallel to the rails, facing each other.

• Rations for padding, such as straw, shall be placed on the floor to avoid injury if a cattle lies down and this shall not be less than 6 cm thick.

• Rations for the journey shall be carried in the middle of the wagon.

• To provide adequate ventilation, upper door of one side of the wagon shall be kept open properly fixed and the upper door of the wagon shall have wire gauge closely welded mesh arrangements to prevent burning cinders from the engines entering the wagon and leading to fire outbreak. Cattle wagons should be attached in the middle of the train.

• Two breast bars shall be provided on each side of the wagon, one at height of 60 to 80 cm and the other at 100 to 110 cm.

• Cattle-in-milk shall be milked at least twice a day and the calves shall be given sufficient quantity of milk to drink.

• As far as possible, cattle may be moved during the nights only. During day time, if possible, they should be unloaded, fed, given water and rested and if in milk, milking shall be carried out.

Transport of Cattle by road or truck

• Transport by road or truck has the convenience of loading at the farm and direct transit to the point of market.

• The absence of repeated handling and disturbance associated with it and consequent avoidance of serious weight loss.

• But the poor road condition and longer distance to be traveled cause comparatively higher cost per km than rails.

• When cattle are to be transported by goods vehicle the following precautions are to be taken namely

• Specially fitted goods vehicles with a special type of tail board and padding around the sides should be used.

• Ordinary goods vehicles shall be provided with anti-slipping material, such as coir matting or wooden board on the floor and the superstructure, if low, should be raised.

• No goods vehicle shall carry more than six cattle.

• Each goods vehicle shall be provided with one attendant.

• While transporting, the cattle, the goods vehicle shall not be loaded with any other merchandise and

• To prevent cattle being frightened or injured, they should preferably, face the engine.

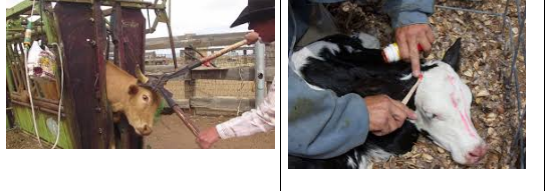

8. In ODF each dairy animal shall bear unique identification number in the form of tag.

Animal Identification

• The proper identification of animals is essential.

• Proper identification enables the producer to keep comprehensive records for milk production, reproduction, health problems, and management practices. The efficient maintenance of this information requires a permanent identification system.

• Several systems of identification may be used. The system selected will depend upon the size of the herd, the environmental conditions, the primary purpose for identifying individual animals, and regulations of federal government and breed-governing bodies.

• There are two basic types of identification: permanent and non-permanent. Permanent identification includes tattooing, ear notches or microchips. Non-permanent identification includes paint, chalk and tags.

9. In ODF identification devices to be used on the animals can be printed ear tags, RFID tags, Barcodes or any other suitable tag which is clearly visible.

Identification of farm animals

• Identification of animals is must, as a requirement in the daily management, to spot and identify a particular animal in a herd/group/flock.

Reasons

• For registration and recording of the parentage in breeding programme / birth

• For individual feeding of animals.

• During milking

• During sale, for participation of animals in the rally, show and exhibition.

• For treating the animal, heat detection etc.

Methods of Identification

• Neck chain/Neck rope

• Ankle band

• Brisket tag

• Tail tag

• Chalk/grease marker

• Black/light coloured paints

• Pictures/sketches

• Photographs

• Ear tattooing

• Ear Notching

• Branding

• Ear tagging

1.Ear tatooing

• It is one of the permanent methods of identification system.

Instruments Required

• Tattooing forceps, tattoo no/letters

• Tattooing ink/paste

Procedure

• Select the tag type (Single piece / Double piece).

• Use the contrasting ink and style based on the skin colour of the animal.

• Invert the ear tag into the appropriate applicator.

• Locate the area in the ear for tagging) (half the way between base and tip of the ear).

• Puncture the ear with applicator if the tags are non-piercing type.

• Apply the ear tag by puncturing the ear with the applicator.

3. Ear notching

• Commonly used in pigs and in beef cattle.

• Notching means making a ‘V’ shaped notches at specific areas of the ear with the help of a sharp scissors or pincers.

• For e.g. a notch in lower right ear is no.1. and notch in lower left ear is No.3.

10. In ODF, mutilations in general are prohibited with some exceptions.

The animals’ distinctive characteristics should be respected; species shall be chosen which do not require mutilation. Mutilations shall be allowed only in exceptional cases and shall be kept to the minimum to reduce suffering of animals.

Dehorning and castration should be performed in a way that causes the least amount of stress to the animal.

Tail docking is not allowed in dairy cattle unless there is a health problem that cannot be cured any other way, such as incurable wound.

Exceptions

In ODF, mutilations such as castrations and dehorning are allowed only if animal suffering is minimized by analgesics & anesthetics, wherever appropriate.

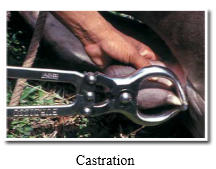

a) Castration- allowed

Castration is the removal or inactivation of the testicles of a male animal. Castration is a common management tool in the beef cattle sector for many reasons, including to:

• Stop the production of male hormones

• Prevent unplanned mating

• Decrease aggression to enhance on-farm safety for handlers and animals

• Obtain price premiums and/or avoid price discounts from feedlots and meat packers

• Produce meat with a consistent quality acceptable to consumers (i.e. higher grade, better marbling)

• Decrease costs of managing bulls (i.e. larger, stronger facilities)

Methods

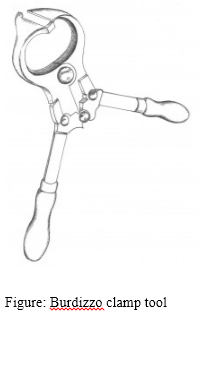

Common physical methods of castration include surgical removal of the testes, or stopping the blood flow to the testes by applying an elastrator band or using a Burdizzo tool.

a. Surgical castration

Surgical castration involves making an incision into the scrotum followed by the physical extraction of both testes. Physical removal is also used when necessary at the feedlot, where intact males are typically 6-12 months of age.

b. Elastrator banding

Elastrator banding involves using a specialized tool to place a purpose-designed rubber ring or latex band around the scrotum, between the testicles and the abdomen. This disrupts the testicular blood supply, causing the testis and the scrotum to slough off 3-6 weeks later. The rubber ring technique is typically performed on at birth or within a few days of birth. This method is relatively rapid in young animals, and has a low failure rate (5%) however incorrect application, particularly in young calves, can result in “belly nuts” which are costly and painful to remedy.

c. Burdizzo

A Burdizzo is a specially designed clamp that is used to physically crush the testicular cord through the scrotal skin. This trauma disrupts the testicular blood supply, causing the testes to die. With this technique, the scrotum remains intact, the testes eventually shrink down, and the animal becomes sterile. This technique is becoming less common in the cattle industry. Compared to surgical castration, this method takes longer and has a higher failure rate (up to 35%), particularly with old or poorly maintained equipment.

b) Dehorning: allowed

Dehorning is the process of removing the horns of livestock. Cattle, sheep, and goats are sometimes dehorned for economic and safety reasons.

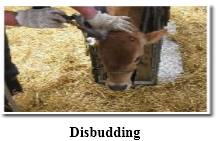

Disbudding is a different process with similar results; it cauterizes and thus destroys horn buds before they have grown into horns. Disbudding is commonly performed early in an animal's life, as are other procedures such as docking and castration.

Reasons invoked in support of dehorning animals include the following:

Reasons invoked in support of dehorning animals include the following:

• Horns may cause injuries to handlers or other animals.

• Horned animals take up more space, causing issues at the feed bunk and during transportation.

• Horned animals may require specialized equipment, such as feeders and angulate crushes.

• In some breeds and in some individuals, horns may grow towards the head, eventually causing injury.

• Horns may become broken, causing blood loss and potential for infection.

• Horned animals may become trapped in fences or vegetation, causing self-injury.

• Horned animals may become more aggressive than those without horns, especially around feed.

Procedure

Dehorning can be performed on older animals and is normally performed with local anesthesia (cornual nerve block) by a veterinarian or a trained professional.

Removal of larger horns is usually performed during spring and autumn to avoid fly season. Sedation may be recommended, especially for larger animals that require increased restraint. Use of longer-term pain medicine, like nonsteroidal anti-inflammatory drugs.

Disbudding minimizes discomfort and risk, and is performed when horns are small "buds" by one of several methods:

• Cauterization is the process of killing the growth ring of the horn using heat. This process is done when cattle are very young, no more than three or four weeks old—that way the horns are not very big. The earlier in the calf's life cauterization is done, the less pain and stress is inflicted on the calf. Cauterization is usually done with a dehorning hot iron after the area is numbed with local anesthesia.

• A curved knife can be used to cut the horn off when the calf is younger than a couple of months old. It is a simple procedure where the horn and the growth ring is cut off to remove the horn.

• For under eight months of age, but after the horns are starting to grow attached to the skull, a cup dehorner or Gigli saw (a type of surgical cutting wire) is used. There are several different types of cup dehorners, but they all serve the same function of removing the horn and growth ring. Since the horn is tougher it takes more force to remove it so tools that provide some leverage are need. Gigli saw wire is used on horns of older calf's horns that have grown too large for the cup dehorners.

• The most recent development in dehorning technology is use of a caustic dehorning paste. The paste is used on calves at less than two days old. The hair around the horn is trimmed back and then the paste is spread all over the horn bud and around the base of the horn on the growth cells. The paste kills the growth ring of the horn and then the horn falls off like a scab when it is healed. However, this method bears a risk of the paste causing injury to the animal's eyes or other tissues if used during periods of rain.

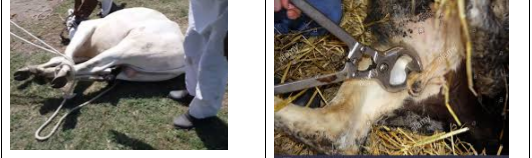

Castration

• Making the animal unable to reproduce is generally known as castration.

• In India and other South-East Asian countries bullocks are extensively used for agricultural operations.

• Buffalo is particularly valued as a draught animal in rice growing areas.

• Male cattle and buffaloes meant for work should be castrated

• Purpose

• To render the animal docile

• To induce faster gain in body weight and to improve the quality of meat.

• To control indiscriminate breeding.

• To prevent certain genital diseases.

• Castration also results in lean and slender neck which facilitates the correct fitness of yoke especially in work cattle.

• Precaution

• Castration should be performed during cold season and strictly avoid rainy season for fear of fly problems.

• Castrated animals should be rested for few days in clean and comfortable pens.

• Optimum Age

• Young animals: within 3 months (Surgical method and elastrator)

• Adult animal: within one year of age (Closed method – Burdizzo castrators)

Methods

1. burdizzo method

• It is also known as bloodless castration. The Burdizzo castrator is used to crush the spermatic cord and thus stopping the blood to the testes.

• This results in atrophy of the testes and stoppage of spermatozoa production.

• After casting, secure the animal. Move the spermatic cord to the side of the scrotum and then clamp the Burdizzo at about 3-5 cm above the testicles and it is held for a few seconds.

• Then repeat this operation on the same cord at a location about 1cm below the first one. This method is safe, quick and less chance of getting infection.

2.Open or surgical method

• Scrotum is opened and testicles are removed, aseptically and the wound is treated with antiseptics.

• In young bulls the cord may be cut as savagely off but in the case of mature bulls the cord should be twisted before severing it.

3. Rubber ring or elastrator method

• A strong and tight rubber ring placed around the cord at an early age of calf.

• This creates constant pressure and the testicles are atrophied and absorbed and the ring drops down.

• Elastrator rings are very painful to the animal and so it is not usually recommended. Optimum age: below 3 months.

Disbudding

• Disbudding means arresting the horn growth at an early age, when the horn root is in the bud stage.

• Horn serves no useful purpose.

• Purpose

• Dehorned animals need less space in the sheds.

• Cattle with horns inflict bruises on each other that may result in heavy economic losses.

• Horned animals are a danger to the operator.

• Dehorned animals can be handled more easily.

• Prevents the occurrence of horn cancer.

• Optimum Age : 15 to 20 days.

Methods

Hot iron method

• A specially designed electric dehorner is used for this purpose. This is bloodless method it may be used at any season.

• The rod heated with electricity has an automatic control that maintain the temperature at about 10000 F, applying it to the horn bud for l0 seconds is sufficient to destroy the horn tissue.

2. Elastrator

• A specially made thick rubber ring applied to the base of the horn.

• The rubber band shuts off circulation and the horn gradually comes off. Small buds drop off in 3 to 6 weeks and large horns may take even 2 months.

• It is a painful method and this method is used on cattle when the horn length is about 5-10 cm.

3. Chemical method

• Caustic potash or caustic soda is the common chemical used for dehorning.

• These are available in the form of paste or solution.

• Clip the hair around the horn buds and surrounding area, a ring of Vaseline to protect the eyes against chemicals.

• Rub the chemical over the buds until bleeding occurs.

4. Dehorning saw or clippers

• When older cattle are to be dehorned a specially designed clippers or saw are used.

• A considerable amount of bleeding may follow the operations.

• To prevent the bleeding the main horn artery should be tied off with a cotton or silk thread.

• This may be done by sliding a sewing needle under the artery to pull the thread in place before tying.

• It is necessary when sawing or clipping the horns, to take about half an inch of skin in order to get at the horn roots.

Extra teat removal

• Normal udder should have four severely placed teats of uniform size. But animals with one and even two extra teats are also seen. Such extra teats may be blind or leaky.

• It should be removed before the calf attains 6 months of age.

• After controlling the calf, the region is thoroughly cleaned and disinfected with Tincture iodine and mark extra teats before removal. These teats are clipped off with scissors.

• Some more tincture is applied after finishing the process. In the older heifer, suture is put in order to arrest bleeding.