|

|

|

Translate this page in your preferred language:

|

| SILAGE MAKING : |

| Back |

Silage:

Silage is high-moisture fodder preserved through fermentation in the absence of air. These are fodders that would deteriorate in quality if allowed to dry. Silage can be made from grasses, fodder sorghum, green oats, green maize or Napier grass. An ideal crop for silage making should;

a. contain an adequate level of fermentable sugars in the form of water-soluble carbohydrates.

b. have dry matter content in the fresh crop above 20%.

c. possess a physical structure that will allow it to compact readily in the silo after harvesting.

Crops not fulfilling these requirements may require pre-treatment such as:

a. field wilting, to reduce moisture.

b. fine chopping, generally 20–25 mm preferred to allow compaction.

c. use of additives, to increase soluble carbohydrates

Harvesting stages:

- Napier grass should be harvested at about 1 meter when

protein content is about 10%.

- Maize and sorghum should be harvested at dough stage that is when the

grain is milky.

- The grains will provide water-soluble sugars and molasses is not necessary when ensiling.

- When ensiling napier grass, molasses should be added to increase the sugar content.

- To improve silage quality, poultry waste and legumes like lucerne and desmodium may be mixed with the material being ensiled to increase the level of crude protein.

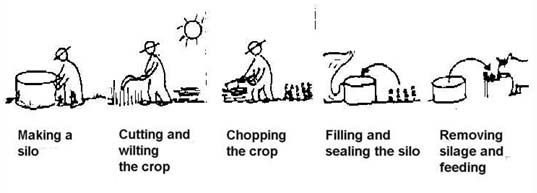

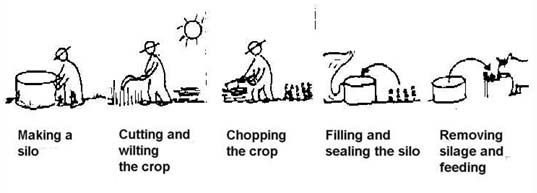

Diagrammatic representation of silage making

Qualities of good silage:

- Well-prepared silage is bright or light yellow-green, has a smell similar to vinegar and has a firm texture.

- Bad silage tends to smell similar to rancid butter or ammonia.

- Natural microorganisms turn the sugars in the plant material or any added as molasses into weak acids, which then act as a preservative. The result is a sweet smelling, moist feed that cattle like to eat once they get used to it.

Storage and feeding:

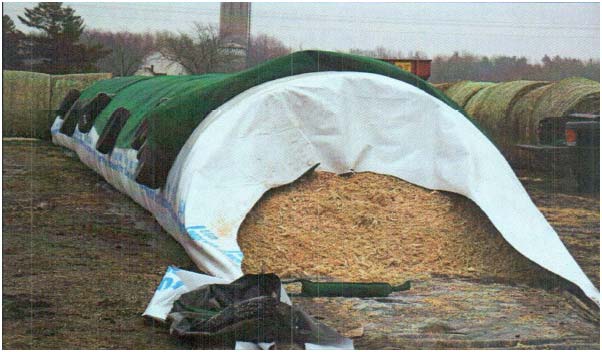

- Tube silage should be stored under shade, for example in a store.

- Rodents like rats that could tear the tube need to be controlled.

- When feeding, open the tube and scoop a layer and remember to re-tie without trapping air inside.

- When feeding from the pit, scoop in layers and cover after removing the day’s ration, making sure the pit is air tight.

- Drainage from the top should be guided to avoid rainwater draining into the pit.

- When feeding from the above-ground method, open from the lower side of the slant, remove the amount you need for the day and re-cover it without trapping air inside.

- To avoid off-flavors in milk, feed silage to milking cows after milking, not before, or feed at least 2 hours before milking.

Losses:

- Nutrient losses may occur during silage making. In the field during cutting, losses due to respiration

during wilting will be about 2% per day. If it rains, leaching may cause some loss.

- Overheating due to poor sealing gives a brown product, which may

smell like tobacco and result in severe damage to nutrients e.g. proteins.

- Effluent losses of 2–10% that occur from moisture seepage contain soluble and highly digestible nutrients; seepage should be avoided by wilting the herbage.

Silage additives:

- During silage preparation, different types of additives can be added to improve the quality. These include

fermentation stimulants. Most inoculants contain Lactobacillus plantarum.

- Fermentation inhibitors include acids such as propionic, formic and sulphuric. Inorganic acids are more effective but are strongly corrosive thus not recommended.

- Of the organic acids, formic is more effective than propionic, lactic or acetic.

- Substrate or nutrient sources (grains, molasses, urea or ammonia) are used when there are insufficient soluble carbohydrates in the material to be ensiled (e.g. legumes, Napier grass, crop residues). They are also used to increase the nutritive value of the silage.

- Molasses can be added at about 9 kg/ton of silage.

Note: Use of additives is not a prerequisite for making good silage, but it is good for problem crops.

|

Silage making procedure

|

|

A pit dug for silage making

( walls are made of concrete to avoid moisture) |

In this pit to make it impermeable to

moisture polythene covering is used |

|

|

|

|

Traditional method of silage making (underground) |

Traditional method of silage making (above the ground) |

|

|

|

|

|

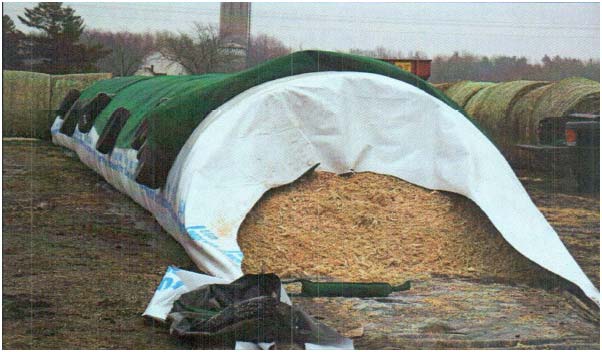

Polythene method of silage making |

One more method of silage making above the ground

|

|

|

| Back |

|

|

Developed by :

|

Jaspal Singh

(Ex. M.V.Sc Scholar ) |

Dr. Pranav Kumar

(Assistant Professor)

|

Amandeep Singh

(Final Year B.V.Sc & AH student) |

|

|

|

|

|

|

Scroll

|

Division of Veterinary and Animal Husbandry Extension Education

Faculty of Veterinary Sciences and Animal Husbandry, R.S. Pura, SKUAST Jammu |

|