|

|

|

| HOUSING |

| Back |

Importance of Improved Housing for Poultry Birds

- To protect chickens against rain and wind.

- To protect chickens against wild animals and predators.

- To reduce outbreaks of disease.

- But provide chickens with fresh air and light.

- To provide the chickens with nests; comfortable dark places to lay, brood and hatch their eggs.

- To increase egg and meat production.

- To improve family diet by eating surplus eggs and chickens.

- To increase family income by selling surplus eggs and chickens.

How to make your chickens comfortable and increase production of meat?

- Chickens need a house which is well protected against rain and wind.

- Chickens need a house with fresh air and ample daylight. Healthy chickens have a nice coat of feathers that can stand the cold easily. Chickens are unable to sweat. They need fresh air to remove body heat this they achieve by opening their beaks.

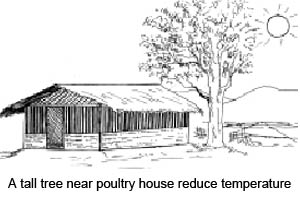

- The housing needs long roofs to give shade to protect chickens from the hot sun. Chickens need a house with enough space to walk around, to feed and drink and to lay and hatch eggs.

- Chickens hate wet feet and dirty, smelling floors. It makes them sick.

- Young chicks cannot stand cold and wet places. It makes them sick

Principles of Good & Economical Housing

- Protection against rain and wind

- Protection against hot sun and high temperature

- Protection against wild animals and predators

- Reduce outbreaks of disease

- Provision of fresh air

- Provision of light inside

- Ample floor space per bird

Housing Models:

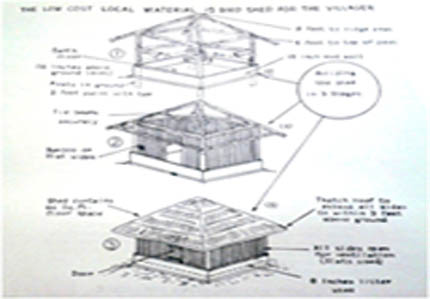

1. Housing with slatted floor

Why? Because then the droppings do not remain in the house. Its stays clean without extra work for the farmer. The ventilation is also better. The floor of the house is slatted and can be made of wood or bamboo. The droppings fall on the ground under the house and lower the risk of diseases.

The space between the bamboo must not be too big. The round side should be up with enough supports across (every 0.5 meter). The underside must not be accessible to the chickens. They should not be able to come and eat the droppings which could spread disease. The droppings/manure should be removed from time to time and put on the gardens or in fields to fertilize the plants.

2. Other housing models

- Housing at large scale poultry farms

- In cages with slatted floor

Remark: in some countries, small cages with many birds per square metre are no longer recommended because of animal welfare concerns.

- In houses with deep litter on the floor

a. Housing with earth floor and litter For chickens to be productive, they need good housing containing feeders, drinkers, nests, roosts or perches and litter. The litter (5 cm) can be made from dried chopped grass, sawdust, crushed maize cobs, rice husks, etc.

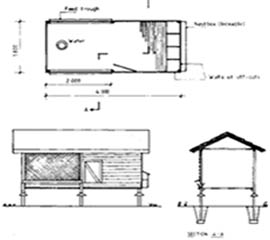

b. Housing on stilts and slatted floor

This type of housing is an alternative to the earth floor with litter. The house is on stilts with slatted floor of wood or bamboo (1 cm thick bamboo sticks, with 1-2 cm space in between). The space under the house, where the manure falls, must be fenced so that the chicken cannot go there.

Advantages are:

1. Better protected against predators like snakes, rats, etc.

2. Little contact with manure (source of parasites and diseases like coccidiosis).

3. No need for litter thus saving labor.

4. Better ventilation and cleaner air.

Rearing systems:

The systems of rearing refer to either single batch at a time (all-in all-out system) or multiple batches of brooding and rearing of broilers.

All-in all-out system:

Under all-in all-out system, the farm will have only one batch of broilers, belonging to the same hatch at any time. Sufficient chicks will be purchased to accommodate the entire farm capacity, reared and marketed in a single lot.This system is more hygienic, lesser sub-clinical infections and horizontal spreading of diseases and thereby lesser mortality rate, better growth rate and improved feed efficiency. However, this system is not suitable for large scale farming and needs higher fixed and working capital per bird.

Multiple batch system:

The multiple batch system consists of rearing of more than one batch of chicks at any time, with a batch interval of 1 to 4 weeks. Here, the farmer is buying day-old chicks and selling grown up broilers at weekly, fortnightly, once in three weeks or at monthly intervals. The chicks are reared for five to six weeks of age, or until they attain the desired body weight and sold for table.

The ideal system for India at present is having 5 to 6 batches of broilers at any time, with weekly interval between batches and “direct retail marketing”. Here, the birds will be marketed daily, from 40 to 54 days of age, based on their body weight, i.e. heavier birds will be sold earlier; giving a chance for weaker birds to have a compensatory growth.

General Considerations in Construction of Poultry House

Selection of location

- Poultry house should be located away from residential and industrial area.

- It should have proper road facilities.

- It should have the basic amenities like water and electricity.

- Availability of farm laborers at relatively cheaper wages.

- Poultry house should be located in an elevated area and there should not be any water-logging.

- It should have proper ventilation.

Layout of poultry farm

A small size poultry farm doesn’t require any special layout as it involves construction of only one house. The medium and large size farms require special considerations for placement of building in the farm premises. The basic principles to be observed for layout are:

- Layout should not allow visitors or outside vehicles near the birds.

- There should be a minimum distance of 50-100 feet between chick and grower shed and the distance between grower and layer sheds should be of minimum 100 meters.

- The egg store room, office room and the feed store room should be located near entrance to minimize the movement of people around the poultry sheds.

- The disposal pit and sick room should be constructed only at the extreme end of the site.

Orientation:

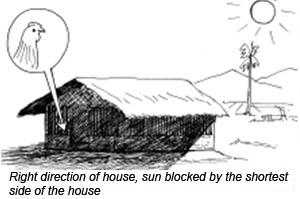

The poultry house should be located in such a way that long axis is in east-west direction. This will prevent the direct sunshine over the birds.

Size:

Each broiler require one square foot of floor space while a layer requires two square feet of floor space under deep-litter system of rearing. So the size of the house depends on the number of birds to be reared.

Length:

The length of the house can be of any extent. The number of birds reared and availability of the land determines the length of poultry house.

Width:

The open sided poultry houses in tropical countries should have a width not more than 22 to 25 feet in order to allow ample ventilation and aeration at the mid-portion.

Height:

The height of the sides from foundation to the roof line should be 6 to 7 feet (eaves height) and at the centre 10 to 12 feet. In case of cage houses, the height is decided by the type of cage arrangements (3 tiers or 4 tiers).

Foundation:

Good foundation is essential to prevent seepage of water into the poultry sheds. The foundation of the house should of concrete with 1 to 1.5 feet below the surface and 1 to 1.5 feet above the ground level.

Floor:

The floor should be made of concrete with rat proof device and free from dampness. The floor of the house should be extended 1.5 feet outside the wall on all sides to prevent rat and snake problems.

|

Type |

Age

(in Weeks) |

Deep-Litter

(ft2) |

| Meat-type chicken |

0-4 |

0.30 |

|

4-8 |

0.75 |

Doors:

The door must be open outside in case of deep-litter poultry houses. The size of door is preferably 6 x 2.5 feet. At the entry, a foot bath should be constructed to fill with a disinfectant.

Side-walls:

The side wall should be of 1-1.5 feet height, and generally at the level of bird’s back height. This side wall protects the bird during rainy days or chill climate and also provides sufficient ventilation. In case of cage houses, no side wall is needed.

Overhang:

The overhang of the roof should not be less than 3.5 feet in order to prevent the entry of rain water into the shed.

Lighting:

Light should be provided at 7-8 feet above the ground level and must be hanged from ceiling. If incandescent bulbs are used, the interval between two bulbs is 10 feet. In case of fluorescent lights (tube lights) the interval is 15 feet.

Poultry can be housed under different systems based on following factors

- Availability of land

- Cost of land

- Type of farming activity.

- Climatic condition

- Labor availability

Different types of poultry houses

- Brooder / chick house: It is used to brood and rear egg-type chicks from 0 to 8 weeks of age.

- Grower house: It is used to grow egg-type birds from 9 to 18 weeks of age.

- Brooders cum grower house: Here, the birds are reared from 0 to 18 weeks of age (entire brooding and growing period of egg-type chicken).

- Layer house: In which birds over 18 weeks of age are reared, usually up to 72 weeks of age.

- Broiler house:In which broilers are reared up to 6 weeks of age.

- Breeder house:: In which both male and female breeders are maintained at appropriate sex ratio.

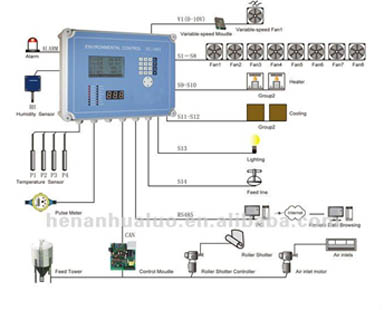

- Environmentally controlled (EC) house:In which, entire environment is manipulated in such a way that is optimum for the birds growth.

Intensive System of Poultry Housing:

In this system the birds are confined to the house entirely, with no access to land outside, and it is usually adopted where land is limited and expensive. This has only been made possible by admitting the direct rays of the sun on the floor of the house so that par to the windows are removable, or either fold or slide down like windows of railway train to permit the ultraviolet rays to reach the birds. Under the intensive system, Battery (cage system) and deep litter methods are most common.

Advantages

- Minimum land is required for farming.

- Farms can be located near market area.

- Day-to-day management is easier.

- The production performance is higher as more energy is saved due to restricted movements.

- Scientific management practices like breeding, feeding, medication, culling etc. can be applied easily and accurately.

- The sick birds can be detected, isolated and treated easily.

Disadvantages

- Birds’ welfare is affected. They cannot perform the natural behavior like roosting, spreading wings, scratching the floor with legs etc.

- Since they are not exposed to outside sunlight and feed sources, all the nutrients should be provided in balanced manner to avoid nutritionally deficient diseases.

- Chances for spreading of diseases are more.

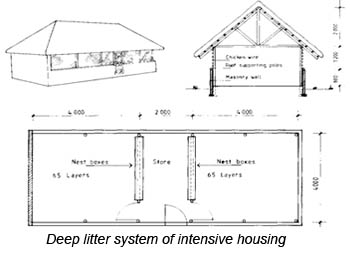

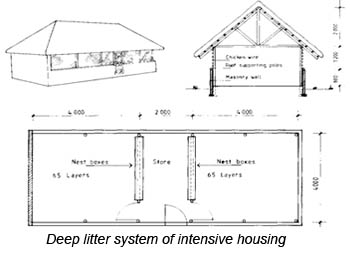

a. Deep litter

- Deep litter houses confine the birds in a building that offers good protection with a reasonable investment.

- If well designed with low masonry walls set on a concrete floor and wire mesh completing the upper part of the walls, the building will exclude rats and birds.

- The principal advantages of this system are easy access for feeding, watering and good protection and reasonable investment.

- The principal disadvantage is the need for high quality litter. If this is produced by the owner, it is of little significance, but if it must be purchased, it becomes an economic factor. In either case, the litter and manure must be removed periodically.

- The deep litter house can be designed up to 9m in width and any length that is needed. Approximately 4 to 5 birds/ m² of floor area is a satisfactory density.

Advantages of Deep Litter System:

- Safety of Birds Birds on rage of even in a netted yard can be taken by wild animals, flying birds, etc. When enclosed in deep litter intensive pen which has strong wire netting or expanded metal, the birds and eggs are safe.

- Litter as a source of food supply:It may come as surprise to learn that built-up deep litter also supplies some of the food requirements of the birds. They obtain "Animal Protein Factor" from deep litter and some work indicates that this could learn that birds obtain sufficient of this to enable to suitable feed ration to be prepared with only a vegetable protein such as groundnut meal included in the feed. The level of vitamins such as riboflavin increases up to nearly three-fold. According to experiments conducted. The combination of this and the Animal Protein Factor is necessary to good hatchability of eggs and early growth of chickens.

- Disease control: Well managed deep litter kept in dry condition with no wet spots around water has a sterilizing action. The level of coccidiosis and worm infestation is much lower watered kept on good deep litter than with birds (or chickens) in bare yards and bare floor sheds particularly where water spillage is allowed.

- Labor saving: This is one of the really big features of deep litter usage. Cleaning out poultry pens daily or weekly means quite a lot of work. With correct conditions observed with well managed litter there is no need to clean a pen out for a whole year; the only attention is the regular stirring and adding of some material is needed.

- The valuable fertilizer: This is a valuable economic factor with deep litter. According to McArdle and Panda, 35 laying birds can produce in one year about 1 tonne of deep litter fertilizer. The level of nitrogen in fresh manure is about 1%, but on well built-up deep litter it may be around 3 per cent nitrogen (nearly 20% protein). It also contains about. 2 per cent phosphorus and 2 per cent potash, its value is about 3 times that of cattle manure.

- Hot weather safeguard: This is an important feature in a hot climate. The litter maintains its own constant temperature, so birds burrow into it when the air temperature is high and thereby cool themselves. Conversely, they can warm themselves in the same way when the weather is very cool. Accordingly, it is a valuable insulating agent.

Disadvantages:

- Because of the direct contact between bird and litter, bacterial and parasitic disease may be a problem.

- Respiratory problems may emerge due to dust from the litter.

- The cost of litter is an additional expenditure on production cost.

- Faults in ventilation can have more serious consequences than in the cage system

|

|

|

| Chicks in deep litter system of housing |

|

Broiler birds in deep litter system of housing |

|

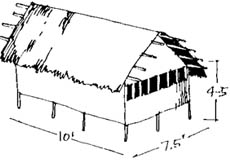

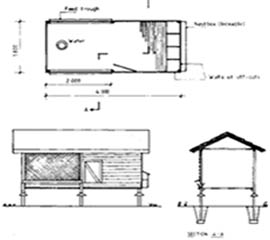

b. Slat or wire floor:

- It is built on treated wooden piers 0.8 to 1m above the ground.

- Ventilation and manure removal are both facilitated, no litter is required and bird density can be 6 to 8 per m².

- Feeding and watering are all efficiently handled from the outside.

- Either a double pitch thatch roof or a single pitch corrugated steel roof may be installed with the eaves about 1.5m above the floor.

- The feed troughs should be equipped with hinged covers and rat guards should be installed at the top of each pier.

- The width of this type of building should be limited to about 2m to allow easy removal of manure and adequate wall space for feeders.

- The building should be oriented east and west and may be of any length.

- If using a slatted floor made sufficiently strong for a person to walk on, then a wider building is feasible as feeders can be placed completely inside where the chickens have access to both sides of the trough.

- The floor is sectioned for easy removal during cleaning out of manure.

- This type of houses is said to be cooler than other types, but the building cost is high and management is more complicated.

Advantages:

- Less floor space per bird is needed when compared to solid floor system.

- Bedding is eliminated.

- Manure handling is avoided.

- Increased sanitation.

- Saving in labor.

- Soil borne infection is controlled.

Disadvantages:

- Higher initial cost than conventional solid floors.

- Less flexibility in the use of the building.

- Any spilled feed is lost through the slots.

- More fly problem.

|

|

|

| Slat-wire floor for poultry birds |

|

Elevated wire floor housing for poultry |

|

|

|

| Slat-wire floor for poultry birds |

Slatted floor system of housing in intensive housing |

Shed with slat floor |

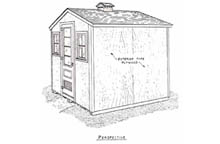

Designs for Small Poultry Structures:

- 8ft. × 8 ft. plywood house for 20 birds

- 3ft. × 4ft. bamboo or mud house with thatched roof for 12 birds.

- Building of a low cost shed for 15 birds.

- A thatch house for 50 broiler birds

Climate Specific Poultry Housing:

Climatic Factors

Temperature

- The over-riding environmental factor affecting the physiological functions of domestic animals is temperature.

- For most farm animals a mean daily temperature in the range 10 to 20°C is referred to as the "comfort zone". In this range the animal's heat exchange can be regulated solely by physical means such as constriction and dilation of blood vessels in the skin, ruffling up the fur or feathers and regulation of the evaporation from lungs and skin.

- At the upper and lower critical temperatures the physical regulation will not be sufficient to maintain a constant body temperature and the animal must, in addition, decrease or increase its metabolic heat production.

- A further decrease or increase in temperature will eventually bring the temperature to a point beyond which not even a change in heat production will be sufficient to maintain homeothermy.

- A very young animal, lacking fully developed temperature-regulating mechanisms, particularly the ability to increase heat production by increased metabolism, is much more sensitive to its thermal environment and requires higher temperatures.

Humidity:

- Poultry do not have sweat glands, so all evaporative heat loss must originate from the respiratory tract.

- In a hot-dry climate evaporation is rapid, but in a hot humid climate the ability of the air to absorb additional moisture is limited and the inadequate cooling may result in heat-stress.

- Too low humidity in the air will cause irritation of the mucous membranes, while too high humidity may promote growth of fungus infections. High humidity may also contribute to decay in structures.

- If possible keep the relative humidity in the range of 40 to 80%.

Radiation:

- Heat gain by radiation can be effectively reduced by the provision of a shaded area.

- As far as the poultry is concerned, the overall radiation loss depends upon the shed structure and ventilation basics achieved or not.

Air Movements:

- Air movements will assist in heat loss by evaporation and by conduction/ convection as long as the air temperature is lower than the skin temperature.

- When the air temperature approaches the skin temperature rapid air movements are experienced as comfortable, but at low temperatures it will lead to excessive cooling of unprotected skin areas (cold draught).

- In addition air movements are required to remove noxious and toxic gases and to supply the animal with fresh air for breathing.

- A wind velocity of 0.2m/s is generally regarded as a minimum requirement, but it can be increased to 1.0m/s, when the temperature is nearing the upper critical, or more when it goes beyond that.

Precipitation:

- Heavy rain my penetrate the feathers of a bird and decrease its insulation value.

- A strong wind can in such circumstances lead to excessive cooling.

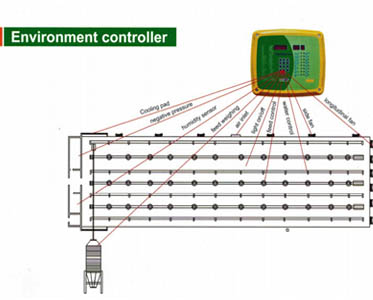

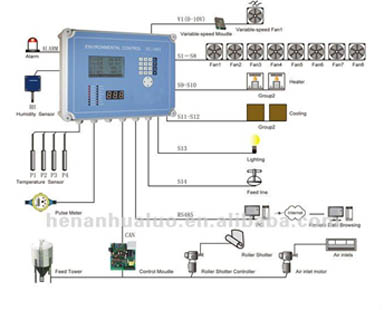

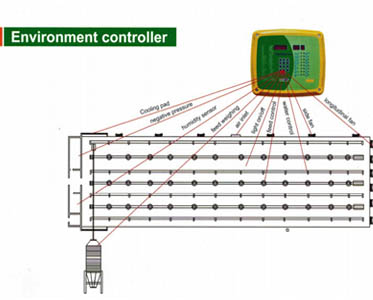

Environment Controlled Housing (ECH):

|

|

|

| Elements of an Environmentally Controlled House (ECH) |

|

Climate control in an ECH (showing brooding stage)

|

What is ECH?:

A Controlled house is one in which inside conditions are maintained as near as to the bird’s optimum requirements. A closed building longitudinally preferably east to west, with big exhaust fans on west side while evaporative cooling pads on east side along with automatic feeding and drinking systems inside.

Components of ECH:

Ventilation

Natural (curtain) ventilation works well only when outside conditions are near what is needed inside the poultry house. In hot weather, strong winds are needed to achieve an acceptable air exchange rate; in cool weather, cold outside air is likely to drop directly onto the birds.

Types of mechanical ventilation systems based on static pressure:

1. Negative-pressure ventilation

Negative-pressure ventilation creates a partial vacuum that pulls air into the house evenly through all inlets, creating more uniform conditions in the house. Negative-pressure fan-powered ventilation creates a partial vacuum in the house, allowing control of the ventilation airflow pattern. Having a tightly sealed house is critical for successful control of in-house conditions in negative-pressure ventilation.

2. Mechanical ventilation systems

Consist of four major components. They are: fans, openings, heaters, and controls.

- Fans and openings control the amount of air exchange in a mechanical ventilation system.

- The openings also have an impact on the air distribution and mixing in a mechanically ventilated poultry barn.

- Heaters provide supplemental heat to maintain desired indoor temperatures during cold weather and when chickens are too small or young to produce enough heat to keep the poultry house warm.

- Controls are needed to adjust ventilating rates (fan controls), supplemental heating rates, and the air velocity rates (fan controls), supplemental heating rates, and the air velocity through openings as weather, bird age and size change.

|

|

|

| Controls in an ECH |

|

Interior of an ECH for broilers

|

Insulation:

A well-insulated building shell is needed to successfully naturally ventilate a poultry house. Insulation helps prevent condensation on the inside surfaces, reduce heat loss in cold weather, and reduce solar heat gain in warm weather. Thermal buoyancy is enhanced by reducing building heat loss through the building shell.

Heaters:

Supplemental heat is usually needed in naturally ventilated grower houses to maintain desired indoor temperatures during cold weather. Different types of heaters are used for supplemental heating in poultry houses including radiant, space, and make-up air heaters.

Feeding:

A feeding control system requires some way of knowing when to turn the feeders on and off. It is important for the same amount of feed to be available at all locations along the feeder. Feed monitoring systems are available to measure the amount of feed consumed by bird.

Lighting:

A monitoring and control system should provide scheduling of lights that is easy to use. It is especially important breeding facilities for precise lighting schedules to be followed. A system than can pre-program lighting schedules over the life of the flock is very useful for management. It is also important to provide the desired intensity of light.

Water:

Water flow monitoring can be used to track how much water the broilers are consuming to quickly detect changes in flock behavior, or to spot problems with the water supply or distribution system. There are 2400 nipples for 30,000 broilers which means as there are 12.5 birds/nipple.

|

|

|

| Exhaust fans in ECH for Poultry |

Shed having all the essentials pertaining to ECH |

ECH for broilers |

|

|

| Back |

|

|

Developed by :

|

Dr.Rahulpreet Singh

( M.V.Sc Scholar ) |

Dr. Pranav Kumar

(Assistant Professor)

|

Dr. Amandeep Singh

(M.V.Sc Scholar, IVRI ) |

|

|

|

|

|

|

Scroll

|

| Division of Veterinary and Animal Husbandry Extension Education Faculty of Veterinary Sciences and Animal Husbandry, R.S. Pura, SKUAST Jammu |

|